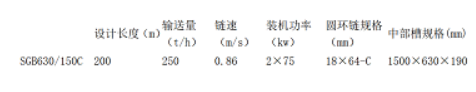

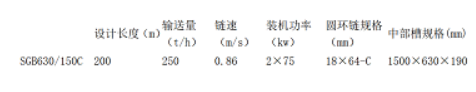

The structural characteristics of SGB630/150C scraper conveyor are mainly composed of the head transmission part, adjustment groove, middle groove, baffle, coal shovel plate, scraper chain, propulsion system, tail transmission part, etc.

Component structure and working principle:

1. Head transmission part: It consists of a head transmission part and a tail transmission part. The electric motor on the tail transmits power to the sprockets on the head and tail through a hydraulic coupling and reducer. The sprockets drive a scraper chain that passes around the head and tail sprockets. The scraper chain runs in the middle groove along the coal transport direction and transports the coal to the unloading end.

2. Middle groove: It is an important component of the machine, consisting of two symmetrically placed groove ribs and a middle plate welded together. One end of the groove ribs is welded with a connecting pin, and the other end is welded with a connecting ear. Four supports are welded to the outer concave parts of the two groove ribs. After intermediate frequency quenching at both ends of the groove, the wear resistance of the groove is improved. When connecting the middle grooves, insert the connecting pin on the groove side of one groove into the concave outer part of another groove side, and use bolts to pass through the connecting ears to connect the grooves together, so that they can deflect 3 degrees from each other in the vertical and horizontal planes.

3. Adjustment groove: There are also head connection grooves and tail connection grooves in the conveyor, which are used to connect the head and tail to the middle groove. In addition, there are one meter adjustment groove and half meter adjustment groove, both of which are designed to adjust the length of the conveyor.

4. Chain wheel component: The structure of the chain wheel is mainly composed of chain wheels, half rollers, and other parts, which are assembled into a whole through bolts.

5. Blind shaft: composed of bearing seat, blind shaft and other parts, its main function is to support the sprocket.

6. Friction tightener: The friction tightener used in this machine is mainly composed of parts such as the lever, pull rod, brake band, brake wheel, and spring. When tightening the chain, the braking force is obtained through the frictional force between the brake band and the brake wheel.

7. Connection groove: It is a transitional connection mechanism between the head (tail) and the middle groove, consisting of connecting plates, middle plates, groove ribs, supports, connection ears, and other parts. When the middle grooves are connected, the connecting pin on the groove side of one groove is inserted into the outer recess of another groove side, and special bolts are used to pass through the connecting ears to connect the grooves together, so that they can deflect 30 degrees from each other in the vertical and horizontal planes.

8. Scraper chain: Installed in the upper and lower grooves of the middle groove, it forms a closed infinite chain by bypassing the chain wheels at the head and tail of the machine. The rotation of the chain wheels drives the scraper chain to run in the middle groove to complete the coal transportation work. Scraper chain is assembled from circular chain, scraper, connecting ring, bolts and other parts. When tightening the scraper chain, the length needs to be adjusted to ensure that the tightness of the scraper chain is appropriate.

9. Pushing beam: Pushing beams are installed below the machine head and tail, which are used by hydraulic thrusters to push the machine head and tail through the pushing beams; When working on the SGB630/150C scraper conveyor, it is necessary to install supports or individual hydraulic supports in the column sockets at both ends of the moving beam. Prevent the conveyor from sliding down and the head and tail from fluctuating due to the traction force of the coal mining machine.

10. Propulsion system: composed of emulsion pump station, hydraulic pusher, hose and other components. The emulsion pump station is the power part of the propulsion system, providing high-pressure liquid required by the hydraulic thruster. The hydraulic slider is connected to the baffle and the connecting plate in the pushing beam through a bidirectional joint, and is used to push the conveyor. The hydraulic pusher is arranged along the entire length of the conveyor, with intervals of 4.5 meters. Users can choose different stroke lengths of the pusher according to different coal mining processes.